Bent wire and bent pipe parts

We process wire and pipe parts by bending and forming them. Our methods include bending, stamping, pressing, extracting, joining, compressing, riveting and clinching. But the non-chipping and chipping forming process in accordance with DIN 8582 also includes welding, turning and drilling. Our bent-wire technology is located in an extremely large machinery park that is optimally suited for larger quantities and repetitive production runs.

Bent forming as bottoming or air bending – that is, with a bottoming tool or as a CNC-programmed air bending method with linear and rotating tools combined with integrated pressing (punching, flattening, pressing, notching, reducing) – can be expanded by adding other elements. This enables welding or automatic assembly, such as attaching a plastic roll to a wire handle.

We provide you with:

- Wire and pipe parts made from all commonly known materials

- In diameters ranging from 2.0 to 12 mm

- In all obtainable profiles: rolled, oval, quadratic, round flat, square

- Made of spring-tempered materials (PT belts, stainless steel)

- Made of soft materials (steel, aluminum, copper, brass)

- For automatic production with a feed length of up to 2000 mm

- With all currently available surface coatings (provided by highly regarded partners)

- With technically achievable thermal treatments (provided by highly regarded partners)

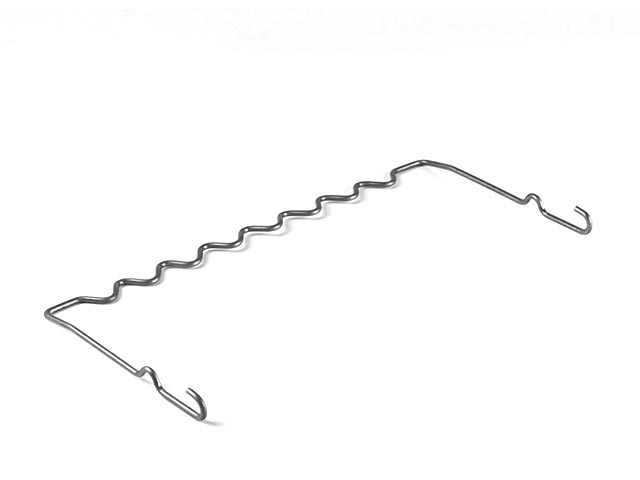

BRIDGE LIFT

Application: Holding system

Material: Steel

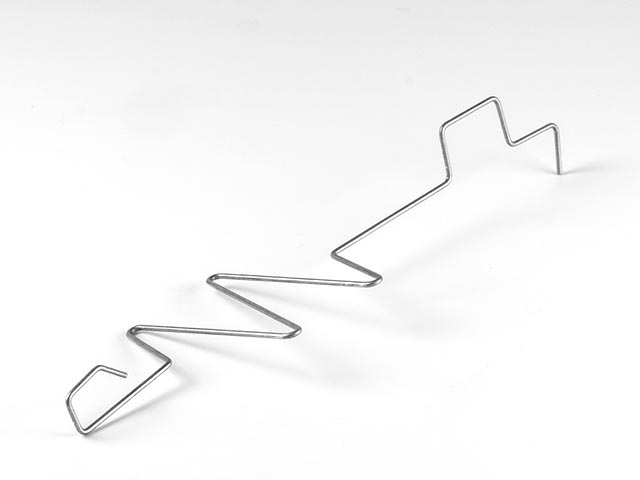

WIRE CLIP

Application: Holding system

Material: Spring steel

ISOFIX

Application: Automotive

Material: Steel

HANDLE CLAMP I

Application: Holding system

Material: Steel

HANDLE CLAMP II

Application: Holding system

Material: Steel

ISOFIX II

Application: Automotive

Material: Steel

ISOFIX III

Application: Automotive

Material: Steel

LASHING BUCKLE

Application: Holding system

Material: Steel

LOCKING CLAMP

Application: Automotive

Material: Steel

Special feature: cold-forged collars

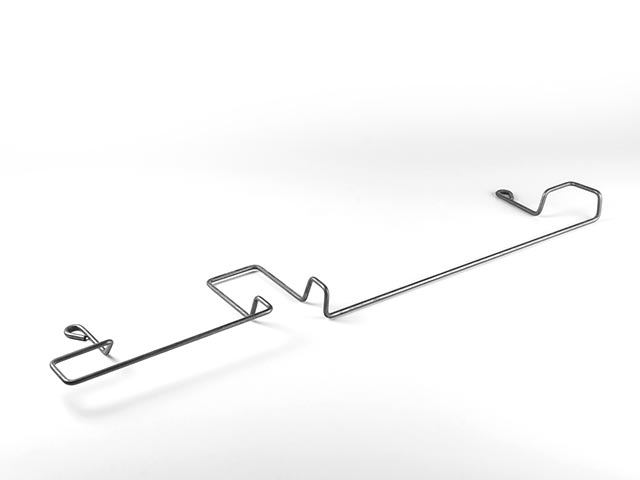

CONNECTING ELEMENT

Application: Construction

Material: Steel

ASSEMBLY TOOL

Application: Construction

Material: Steel

CEILING HANGER

Application: Construction

Material: Steel

Special feature: stamped and cut

BOLTS I

Application: Automotive

Material: Steel

Special feature: stamped and cut

BOLTS II

Application: Automotive

Material: Steel

Special feature: Head shape

BOLTS III

Application: Automotive

Material: Steel

Special feature: different forging levels

SQUARE PIN

Application: Construction

Material: Steel

STEP CLAMP

Application: Holding system

Material: Steel

Special feature: flattened and punched

LATERAL FRAMES

Application: Holding system

Material: Steel

WOOD COVER TIGHTENER

Application: Holding system

Material: Steel

Special feature: Patented

ARMREST

Application: Automotive

Material: Steel

HOLDER

Application: Automotive

Material: Steel

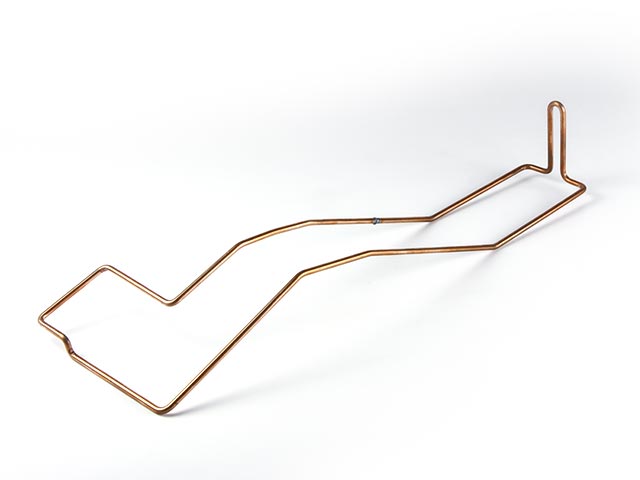

COOLING COIL

Application: Electric

Material: Aluminum

GUIDE TUBE I

Application: Automotive

Material: Steel

GUIDE TUBE II

Application: Automotive

Material: Steel

GUIDE TUBE III

Application: Automotive

Material: Steel

GUIDE TUBE IV

Application: Automotive

Material: Steel

V-BOLTS

Application: Electric

Material: Steel

Special feature: inside grating