Assemblies

The joining of manufactured bent wire and bent pipe parts as well as cold-formed parts and stamped and bent-stamped parts to welded assemblies is accomplished in part through fully automatic welding systems. In this way, we guarantee our customers optimal quality and efficiency.

Our machinery park features traditional resistance welding machines and complex, robot-guided spot welding systems. Through our highly regarded external partners, we have access to robot-guided MIG and MAG welding systems. Significant welding parameters on all welding points are checked and documented in a process where each welding point in turn has a clear and unequivocal assignment within the welding assembly, since each welding assembly has its own coding. Where a welding parameter is found to be not in order, the welding assembly is automatically cut out and destroyed.

Various standard parts such as screws, nuts, rivets, bolts and pins are put together into assemblies along with our stamped and bent-stamped parts through a separate work process using torque-checking equipment specially designed for this process. The material rivet feeding process is directly and entirely automatically built into the stamping and bent-stamping tool and executed there. The assembly is therefore constructed simultaneously with the form-stamping process.

An assembly is also created, however, by subsequent plastic overmolding of bent wire and pipe parts as well as cold-formed parts. Two overmolding systems are used, each having a butterfly table with maximum tool spans of up to a maximum of 750 x 500 mm and a clamping force of up to 160 tons.

We provide you with:

- Welding assemblies with complex geometries

- Assemblies made from bent wire and pipe parts as well as cold-formed parts

- Combinations of stamped and bent-stamped parts

- Combination of bent wire and pipe parts as well as cold-formed parts with stamped and bent-stamped parts

- Use of resistance welding and spot welding processes

- Use of MIG and MAG welding processes (provided by highly regarded partners)

- Screw, bolt and pin assembly for stamped and bent-stamped parts

- Fully automatic rivet feeding into the stamping and bent-stamping tool

- Plastic overmolding bent-wire, bent-pipe and cold-formed parts in accordance with customer request

- With all currently available surface coatings (provided by highly regarded partners)

SPRING BASE

Application: Automotive

Material: Spring steel

Special feature: Hybrid component (spring steel/plastic)

STARTING AID

Application: Automotive

Material: Copper

ISOFIX

Application: Automotive

Material: Steel

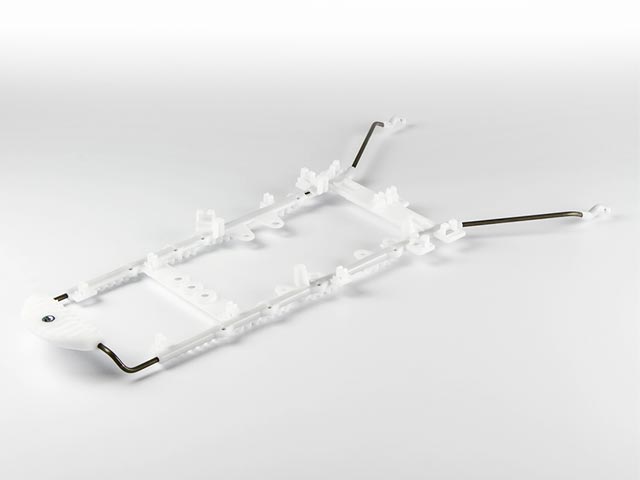

WIRE FRAME

Application: Automotive

Material: Steel

BRACE

Application: Automotive

Material: Steel

BUSBAR

Application: Automotive

Material: Copper

RESILIENT ROD

Application: Automotive

Material: Steel

Special feature: Flocked

ARMREST

Application: Automotive

Material: Steel

ELECTRODE

Application: Construction

Material: Steel

Special feature: Hybrid component (steel/plastic)

CONTACT BAR

Application: Electric

Material: Stahl

Special feature: clinched